1 – Acquiring the motor

1– Acquiring the motor

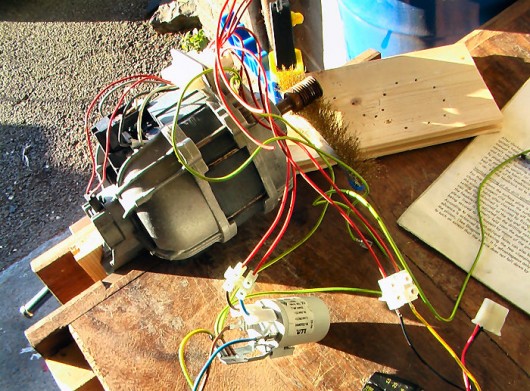

For this you are either going to buy a motor, or scavenge and reuse one. Favouring the latter and more environmentally-friendly option, these writings assumes you will scavenge one. The picture shows an old washing machine motor salvaged from a machine my parents were throwing out. These tend to be a good and surprisingly plentiful (keep your eyes out) source of one horsepower series wound commutator motors. It should provide plenty enough power to drive a small wood lathe like the one I am planning.

If you do get a washing machine motor try and grab the whole machine – then in the comfort of your own home you can take your time to work out how the wiring went. If like me you were on a time budget to get it away from your parents sub-Arctic outside shed just cut it out and get as much of the electronics as possible.

To extract the motor, turn the machine upside-down and you should be able to see the motor. It is now simply a case of unbolting it from its mountings.

These motors can be run off both DC and AC making them quite versatile little beasties.

In the picture I am testing the motor with a DC bench supply, made from an old computer PSU (power supply unit – check out Sitnalta’s instructable). DO NOT CONNECT THE MOTOR TO MAINS VOLTAGE without any load attached. Series wound motors have no theoretical limit to their speed and the centrifugal forces can fling the motor armature apart! Even with a modest load a direct connection to 240V mains is a bad idea, as the speeds are likely to strain the bearings, brushes and frame – all of which are not designed for unlimited power without a hefty mechanical load.

Another way to test a motor of this sort without a bench-top supply is to attach a 1000W electric heater wire between the brushes. The current passing through the resistance wire should be enough to limit the speed of the motor.

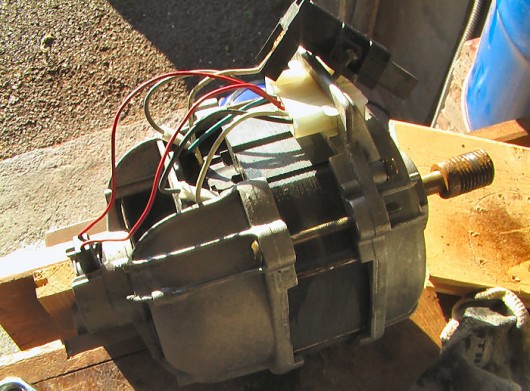

The series wound washing machine motor will look something like this

If you can, salvage other bits that look important. You can make do without but if you can get em…

Make sure to fasten the motor to something solid so it doesn’t fly across the room when you first switch on. Here I use the home made bench (reclaimed wood) with vice to hold the motor firmly. This was one of my first projects – If you don’t have a bench, get building – making a lathe without one would be very tricky.

Even on with my 12V bench top supply I thought it wise to start with some load on the motor shaft. This wire brush clamped in place did the trick and helped clean some of the rust off too ; )

Unless your a wiz with electric motors already, this may require some research and learning. That’s half the fun!

Motor brushes – worth unscrewing to examine – check for pitting or excessive wear. They can usually be replaced relativity cheaply if necessary.

While the brushes are out check the surface of the commutator. Unless the motor is brand new it will be blackened where the carbon brushes have rubbed – that’s ok, just check for any uneven segments or pitting.. If there is any it’s probably worth looking for a new motor, especially if there is sparking between the brushes and commutator when run at low 12V bench supply speeds.