7 – Making the headstock

7 – Making the headstock (front and back panels)

Here I decided how high the centers would be, which among other things (like common sense and self preservation) will determine the maximum radius of wood that can be turned. I wanted the ability to make food plates, which can come from stock that is quite thin (therefore not overly heavy) but has a reasonably large diameter.

Remember the further the drive shaft is from the bed the more leverage it has and the more likely it is to do cheeky twisting, wobbling and other dangerous things. So it is a compromise of size and strength…

Once I had decided that (it was partially determined by the materials I had available), I began by cutting two equal sized pieces from the 8mm thick sheet of metal. I already had two stainless bits which would add a tough outer shell and little bit of rigidity.

Now we need to decide where and how we will fix the front and back faces. I wanted to make them identical front and back panels – I did this by clamping them together and, where possible, drilling through one and into the other a ways so it was easy to resume drilling at the right place.

Again see the pics and their descriptions for more.

Some general advice on drilling… This would have been easier with a drill press (that will have to be a future project though), but you can make do with a decent hand drill – and get quite skilled at using it in the process.. Use plenty of light oil on the drill bits, and go at a slow speed. If you go fast you will harden the steel your trying to drill and dull the drill bit, making it really difficult. Using sharp drill bits helps a lot! (see http://www.instructables.com/id/Sharpen-Your-Drill-Bits/)

Always clamp things your drilling. It’s easier and safer, and you can concentrate with both hands on making a straight hole.

Consider what size bolt you are going to use in advance, so you can choose the right size bit. You can download tables with the correct corresponding sizes and print it out.

Or, a good rule of thumb is to take the bolt diameter and take away the thread pitch to give the size of drill bit.

e.g. If i want to tap a 6mm thread (because I want to use a 6mm bolt) and if the thread pitch is 1mm, then the drill bit size would be 6mm – 1mm = 5mm drill bit. Rule works just as well with imperial too.

Using scraps I consider the height and placement of the drive shaft in relation to the bed.

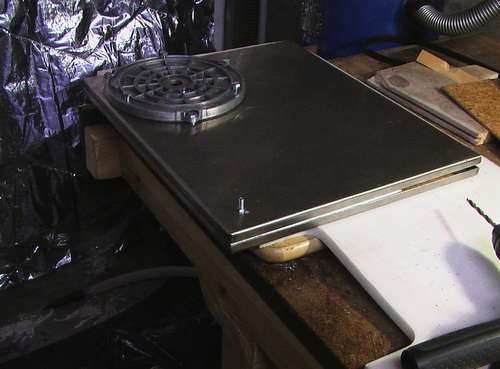

This is the large plate of steel I scavenged. It is about 6mm thick and was a challenge for the jigsaw. I clamped it up so that I could cut a straight line using a bit of alu channel as a cutting guide fence. The idea is to make two identical plates to make the front and back of the headstock.

The first major test was to cut out a big hole that one side of the motor housing would fit into. I used a fairly cheap hole saw I had for plumbing… I used plenty of oil and had periodic brakes to prevent overheating (of both drill and hole saw).

Hole complete, testing the fit of the front bearing housing (which I have cleaned up a bit). I have drilled, tapped three holes and bolted it on.

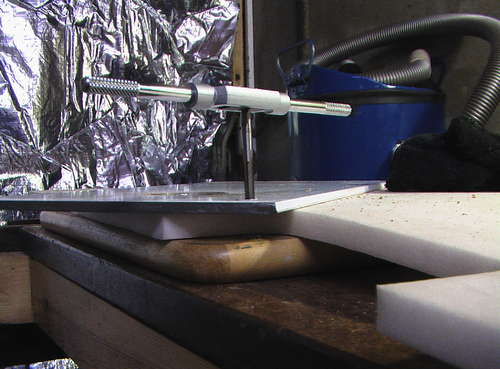

To ensure the drive shaft would sit horizontal and straight I drilled through the front and back panels with them sandwiched together. This way the bearing housings will be in line.

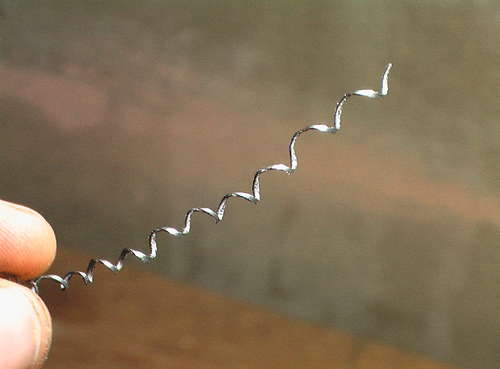

If the drilling of holes is going well and you have good sharp drill bits, the swarf will look something like this. Remember one sharp quality drill bit is worth a box full of cheap ones which are going to be an annoying faf and hamper your creative stylee.

Tapping the threads – Starting is the tricky bit. Use a light machine oil, turn three quarters clockwise, one quarter anti, till you get through. Taking your time, and make some good strong threads.

We need to ensure the front and back panel stay symmetrical so that everything lines up nicely, and runs true.

I am seeing what it might be like with the shaft and rotor in the housings. It is starting to look like something.