Making Quick Clamp Hold Downs from Scrap

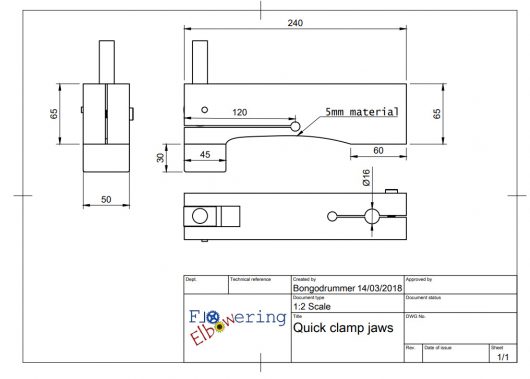

The bar of the clamp is made from one round steel bar about 280mm (11″). Mine was 16mm (5/8 inch) diameter, which fit the Bosch mitre saw clamp slots just right after a bit of knurling. If you were making this for your workbench, the diameter would be less crucial and you could use whatever scrap bar you can get hold of (or see a search like this on ebay)…

The free plans are drawn up in Fusion 360, so if you use that or want to have a look you can access and tinker with the 3d files here. Otherwise the drawings below can be printed out – the pdf is at 1:2 scale (click here to download pdf Quick Clamp Jaws Plans v1). That in combination with the build video should easily get you through.

The clamp body/jaw is best made from some straight grained hardwood. I was using an unidentified piece of pallet wood, that I could tell was hardwood from how heavy and dense it was, how hard to dent with the fingernail etc. The sawdust smelled like bacon… Of particular importance is the lower section of the clamp jaw, which should be completely defect free, as this is the bit that will be flexing as the clam is operated.

The clamp body/jaw is best made from some straight grained hardwood. I was using an unidentified piece of pallet wood, that I could tell was hardwood from how heavy and dense it was, how hard to dent with the fingernail etc. The sawdust smelled like bacon… Of particular importance is the lower section of the clamp jaw, which should be completely defect free, as this is the bit that will be flexing as the clam is operated.

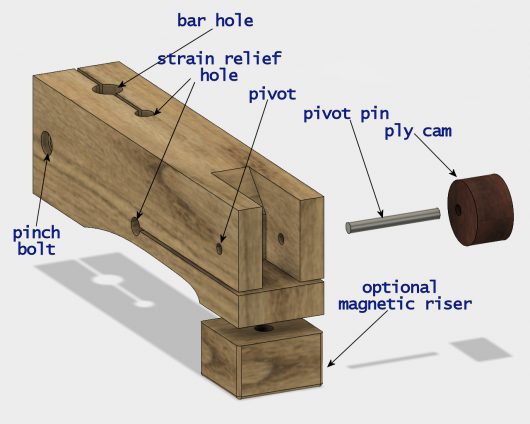

The biggest woodworking operation on the clamp head, is to remove the area that the cam will be located. I used a 20mm forstner bit and a chisel to do this.

Two 10mm (3/8″) strain relief holes are drilled at the end of each of the saw slits on the clamps jaw. The slit on the back allows for fine adjustment of the grip the clamp head has on the round bar. There is an M8 pinch bolt threaded into the wood that adjusts this. You could make this a star handled bolt if you have one handy. I don’t anticipate adjusting it much though.

The clamp plans show an optional magnetic riser that can be easily added to clamp thinner work pieces.

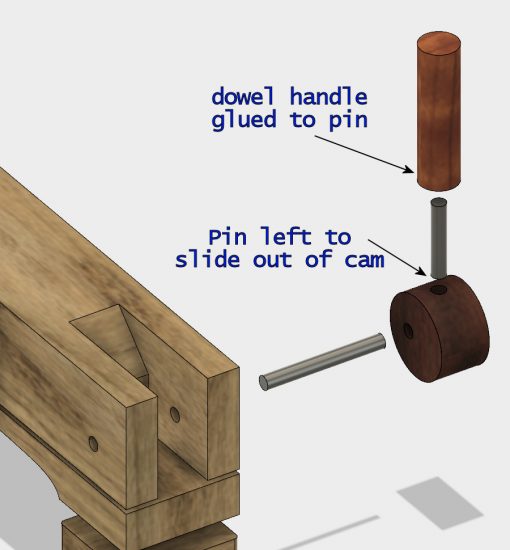

The cam is just a ~35mm (1 3/8″) wooden plug made from a 40mm hole-saw. This would probably be best made from a good quality ply wood for multi-directional strength. If you like woodworking you could make your own with a few hardwood off-cuts, and say 4 to five thin layers. I personally gambled and just used the densest, close grained scrap I could find. Once you have your plug drill an off centre hole (see plans and check out the vid), and that’s it – you have your cam!

Here’s the clamp in action on the Bosch mitre saw. Cutting aluminium, is now much more appealing!

I hope you find some use in this little wooden power clamp/hold down. Please share with your woodworking buddies! Any questions just ask.

October 8th, 2018 at 8:19 am

been after a more flexible versatile hold down for my bench. Bingo

December 23rd, 2018 at 11:05 pm

Great hold down. I’m going to make one.

March 11th, 2019 at 6:53 pm

Any tool that can be hand made from recycled materials is spot on, I look forward in building one of these myself, thanks for a great idea.

June 19th, 2021 at 9:55 am

greetings

do you sell this clamp ?

sincerely

william lewis

June 19th, 2021 at 1:52 pm

Hi William,

Thanks for asking, I’m afraid not. Maybe once the cnc is complete… ;)