2.5 –Speed Control (part 5 – Improving speed regulation and low speed torque)

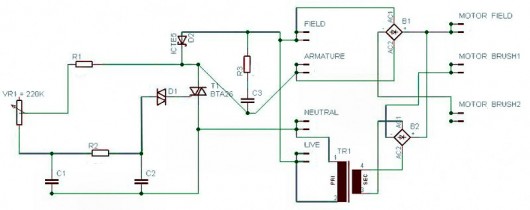

An optional further increase can be had in speed regulation and low speed torque by effectively converting the machine to a direct current shunt wound motor. To do this we rectify the speed controller output and supply the motor with DC (direct current). We also use a very low voltage (and high current) to energize the field coil.

As shown in the diagram, we still keep the 240V DC running through the field coil as well, this gives the benefit of reducing starting current surges. It is important to wire the two rectifiers such that they are pushing current in the same direction through the field coil (see diagram).

To do this we will need the optional components mentioned earlier – a transformer (100VA should suffice – but see what you can find) and bridge rectifiers (these get quite hot, high current ones are a good idea). The transformer, being the most substantial electronic component is definitely worth scavenging (A new transformer is likely to set you back a good 15pounds). To our shame, in Britain at least, you will not have any trouble finding one. Likely places for the transformer are junked stereos, amplifiers, power supply boxes (though most wall warts are not up to it), and other electronic devices that routinely get thrown away.

After flirting with the idea of using a rewound microwave transformer (and discarding it as overkill), I came across an old-school Spectrum power supply at the local tip (which is essentially a transformer with a rectifier and smoothing capacitor) – just the ticket! It is only rated (on the case) to 2.1A at 9V DC and I was needing more like 5A, but after testing it seemed the rectifying diodes were the weak link, and the transformer, when not completely sealed in plastic, as it was originally, actually runs nice and cool when delivering a steady 5A.

Lots of mains voltage and danger! Plan your test before plugging in. Do it carefully and unplug.

July 13th, 2011 at 9:06 pm

Looks like there is a mistake in the diagram – there is a short across the field winding rectifier…

http://i56.photobucket.com/albums/g163/excession000/FE_short.gif

July 14th, 2011 at 9:55 am

Hay Gary,

Thanks for pointing this out, not sure how that error snuck in there. Have changed the schematic to correct this. I have also tried to clear it up a bit – if you click on it now you can access a larger version!

I will also try and add more detail to do with how the motor field coil is connected. [edit: Done.]

July 15th, 2011 at 5:38 pm

I don’t want to split hairs but…. all the resistors on the schematic are 22k yet the parts list has 22k, 4k7 and 100R.

Just making up the circuit now…

July 17th, 2011 at 3:02 pm

Ooops. Go off the parts list Gary, the specs there are correct – diagram changed.

March 9th, 2012 at 11:56 am

Hi, could this controller be used on a 240V vacuum cleaner motor to control it’s speed?

Cheers.

March 9th, 2012 at 12:04 pm

Hi Barry,

It depends on the particular motor, but almost certainly, yes! This controller will work for all brushed universal style motors – all the vacuum cleaners I have seen have them :)

It is particularly good for this kind of ‘air moving’ application because the load on the motor is fairly constant. Thus you can leave out the additional transformer and rectifier (added in Part 5) which help to give better speed regulation – this is only needed when the loading of the motor changes often.

March 9th, 2012 at 12:59 pm

Thanks, Bongo, I’ll build it and see how I go!

Cheers

November 15th, 2012 at 11:54 am

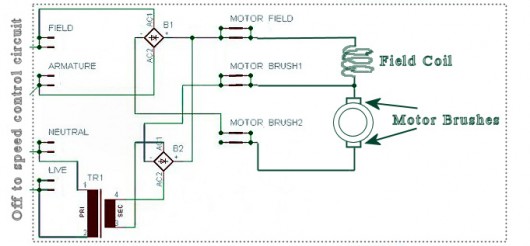

Just a question on the term you use because I have to do the best translation.

Live and Neutral are the normal plug of 220V.

Field is the plug on the stator of the motor

Armature is the plug on the rotor of the motor.

Is that right?

Thank you

November 16th, 2012 at 10:48 am

Hi Fabio.

Yeah that sounds about right – armature goes to the carbon rushes, which in turn sends current to the rotating coils. Field is the stationary copper coils on the outside.

Hopefully the last diagram on this page makes it clear.

December 22nd, 2012 at 1:12 pm

Hi

There is an IC for controlling these motors TDA1089

if you use one you will have a very stiff speed control.(One which not vary with load)

Cheers Keith

December 31st, 2012 at 11:25 am

Hi Keith.

I think that will bw more easy with the controller TDA1089 but i can not find it with google.

Can you please send me some link where i can find information about that?

Thank you

January 3rd, 2013 at 12:38 pm

Hi,

I think it was the TDA1085 I was talking about all the info is on my site (they deleted it). I have used these motors for all sorts of stuff and they are superior to the induction motor inverter combination which is often used for variable speed.

Cheers Keith

January 3rd, 2013 at 2:00 pm

Dear Keith,

can you please post the electric diagram with the TDA1085 inside?

Thank you

Fabio