9 –Mounting the motor & the other centre support

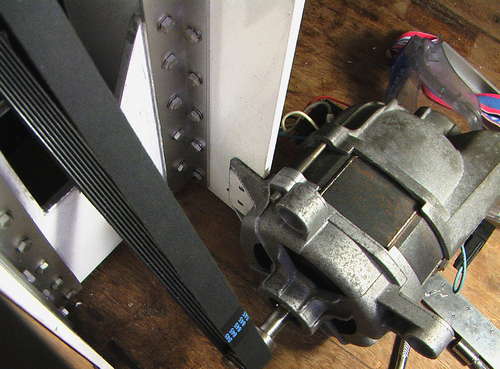

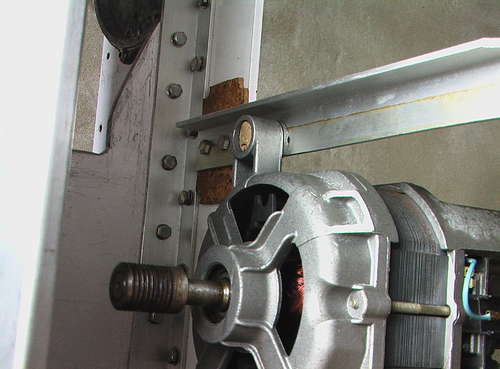

I found that I could bolt the part of the motor housing that previously held the electrical connector directly to the back panel. This didn’t look quite strong enough, so I also used one of the ‘proper’ motor mounts, bolted to some aluminium channelling, which in turn bolted to the back panel.

Using a tailors tape measure or a piece of string the belt length can be calculated. For this application a poly-v belt is best. This is because only the relatively flat poly-v belts can handle the sharp radius of the small motor drive shaft. Standard v-belts would need bigger pulleys. The chances of scavenging a correctly sized belt seemed minimal so I ordered mine over the phone, it was £8.

Apparently the belt tension is about right when you can just twist the belt by 90degrees but not much further without using force. Super subjective I know, so it is a good idea to design some adjustment into the motor mount.

Tapped holes now in operation and firmly fixing front and back panels to the alu centre panel. Here I am considering how the motor will mount.