Hacking my Band Saw

The most innocuous, but time saving has been the quick release blade tension handle. This simple cam mechanism makes it super easy to release the blade tension so I can quickly change blades, or just leave the bandsaw a few weeks without worrying the blade dig in and deform the tyres.

The cam is very simple: it’s an off cut disk of mild steel, with approximately 1/3 the width machined out, as per pic below. I tap a hole that a metal bar (the handle) gets screwed into…

Then it’s just a case of drilling an off centre hole, which is pinned through with the ‘wheel pulling rod’ and the cam itself is complete. All this makes more sense in the video, but essentially rotation of the cam pulls up on the tension rod.

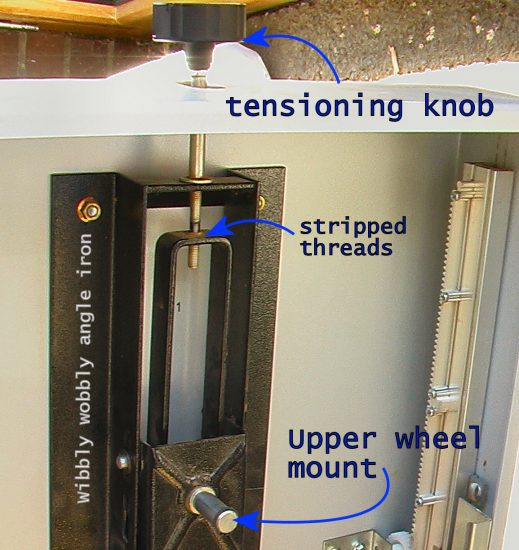

This all replaces the mechanism below. As I show in the vid, this whole area also gets some significant strategic reinforcement.

I have written about the importance of dust collection at length before here, and specifically in relation to the bandsaw here, but my current thinking on this topic and the system I use now, is simple and quick, and takes dust from source…

There are many more points of discussion and modifications on the saw in the youtube video. Some of them are : A mobile base, a load of attempts to increase rigidity in the steel frame, vibration damping both with sand and epoxy granite. setting up and dressing the blade guides and adding a worklight, etc, etc. If you want to spend 12 minuets geeking out about bandsaws, just watch the video.

December 29th, 2018 at 6:07 am

Hello,

Thanks for sharing this info. I think it will very helpful for me.